Wire Mesh Deep Processing Products, As A Perfect Combination Of Modern Industry And Art, Showcase The Exquisite And Diverse Material Processing Technology. These Products Are Based On Various Types Of Wire Mesh (Including Metal Wire Mesh, Polyester Fiber Mesh, Nylon Mesh, Etc.), And Are Endowed With Unique Performance And Appearance Through Fine Cutting, Stretching, Weaving, Electroplating, Coating And Other Deep Processing Technologies.

|

|

|

|

|

|

The main filter material of the corrugated filter element is made of stainless steel fiber sintered felt and stainless steel woven mesh.

The corrugated filter element has the characteristics of large filtration area, strong dirt holding capacity, easy cleaning, high temperature resistance, and economical use

Application industry:

1. Polymer industry: production fields such as synthetic fibers, plastics, film, etc;

2. Petrochemical industry: Petrochemical industry, petroleum refining, paint refining, etc;

3. Pharmaceuticals and food: synthesis, refining, catalytic recovery of drugs and food;

4. Machinery and ships: hydraulic production lines and cutting oil, gas and natural gas flow control fields;

5. Sterilization and filtration for air purification and water treatment;

6. Other: High temperature, high viscosity, high-pressure fields;

Bag filter basket

The bag filter basket is the filtering core part of the bag filter, mainly playing a supporting role. At work

Place the filter bag into the filter basket, and the liquid flows in from the inlet. After being filtered by the filter bag, it flows out from the outlet, blocking impurities

Cut in the filter bag, can continue to be used after replacing the filter bag; Its characteristics are novel structure, small size, and easy operation

Simple, flexible, energy-saving, efficient, and highly applicable, etc

Basket Filter Basket

The Basket Filter Basket Is An Important Component Of The Basket Filter, Used At The Inlet Of The Pump. The Filter Screen Of The Basket Filter Can Be Quickly Disassembled And Cleaned, And Is Generally Used On Pipelines That Require Long-Term Filtration; When The Liquid Enters The Filter Basket Through The Main Pipe, Solid Impurity Particles Are Blocked Inside The Filter Basket, While Clean Fluid Passes Through The Filter Basket And Is Discharged From The Filter Outlet; When Cleaning Is Needed, Simply Remove The Detachable Filter Basket

Working Principle And Characteristics:

The Basket Filter Basket Is An Important Component Of The Basket Filter, Used At The Inlet Of The Pump. The Filter Screen Of The Basket Filter Can Be Quickly Disassembled And Cleaned, And Is Generally Used On Pipelines That Require Long-Term Filtration; When The Liquid Enters The Filter Basket Through The Main Pipe, Solid Impurity Particles Are Blocked Inside The Filter Basket, While Clean Fluid Passes Through The Filter Basket And Is Discharged From The Filter Outlet; When Cleaning Is Needed, Simply Remove The Detachable Filter Basket, Process It, And Reinstall It; Its Characteristics Are: Compact Structure, High Filtration Capacity, Low Pressure Loss, Wide Applicability, Easy Maintenance, Low Price, Etc

Application:

1. Weakly Corrosive Materials In Chemical And Petrochemical Production, Such As Water, Oil Products, Ammonia, Hydrocarbons, Etc.

2. Corrosive Materials In Chemical Production, Such As Caustic Soda, Soda Ash, Concentrated And Dilute Sulfuric Acid, Carbonic Acid, And Aldehyde Acid.

3. Low Temperature Materials In Refrigeration, Such As Liquid Methane, Liquid Ammonia, Liquid Oxygen, And Various Refrigerants.

4. Materials With Hygiene Requirements In Food And Pharmaceutical Production, Such As Beer, Beverages, Dairy Products, Syrup, Etc

T-Shaped Filter Basket

The T-Shaped Filter Basket Is An Important Component Of The T-Shaped Filter. The Diameter Of The Pipes Used In T-Shaped Filters Is Generally Large, And The Internal Filter Screen Can Also Be Cleaned, Replaced, Etc. When The Fluid Enters The Filter Cartridge With A Certain Specification Of Filter Screen, Its Impurities Are Blocked, And The Clean Filtrate Is Discharged From The Filter Outlet. When Cleaning Is Needed, Simply Remove The Detachable Filter Cartridge, Process It, And Reinstall It; Its Characteristics Are: Compact Structure, High Filtration Capacity, Low Pressure Loss, Wide Applicability, Easy Maintenance, Low Price, Etc

Working Principle And Characteristics:

The T-Shaped Filter Basket Is An Important Component Of The T-Shaped Filter. The Diameter Of The Pipes Used In T-Shaped Filters Is Generally Large, And The Internal Filter Screen Can Also Be Cleaned, Replaced, Etc. When The Fluid Enters The Filter Cartridge With A Certain Specification Of Filter Screen, Its Impurities Are Blocked, And The Clean Filtrate Is Discharged From The Filter Outlet. When Cleaning Is Needed, Simply Remove The Detachable Filter Cartridge, Process It, And Reinstall It; Its Characteristics Are: Compact Structure, High Filtration Capacity, Low Pressure Loss, Wide Applicability, Easy Maintenance, Low Price, Etc

Application:

1. Weakly Corrosive Materials In Chemical And Petrochemical Production, Such As Water, Oil Products, Ammonia, Hydrocarbons, Etc.

2. Corrosive Materials In Chemical Production, Such As Caustic Soda, Soda Ash, Concentrated And Dilute Sulfuric Acid, Carbonic Acid, And Aldehyde Acid.

3. Low Temperature Materials In Refrigeration, Such As Liquid Methane, Liquid Ammonia, Liquid Oxygen, And Various Refrigerants.

4. Materials With Hygiene Requirements In Food And Pharmaceutical Production, Such As Beer, Beverages, Dairy Products, Syrup, Etc.

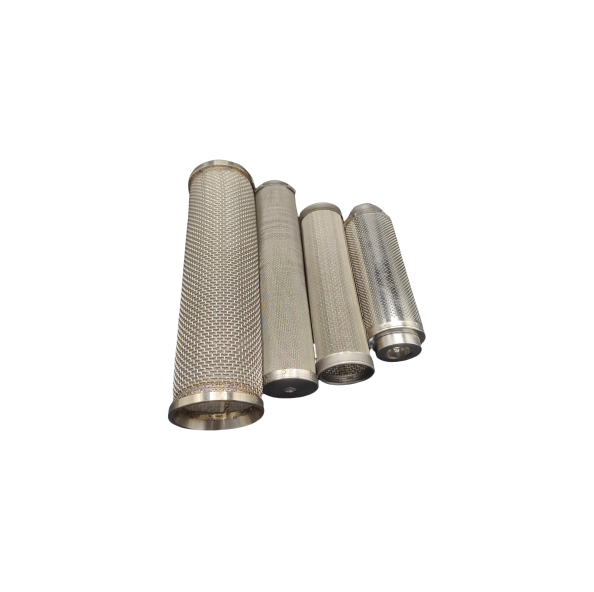

Metal Filter Cartridge

Metal Filter Cartridge, Made Of Single-Layer Or Multi-Layer Metal Mesh, With The Number Of Layers And Mesh Size Depending On Different Usage Conditions And Purposes. It Has Good Filtration Performance For 1-500um Particles And Liquids, With A Large Flow Rate Per Unit Area. After Cleaning, It Can Be Reused Repeatedly. Its Characteristics Are High Absolute Concentricity, High Pressure Resistance, Good Straightness, No Burrs, And Long Service Life.

Working Principle And Characteristics:

Metal Filter Cartridge, Made Of Single-Layer Or Multi-Layer Metal Mesh, With The Number Of Layers And Mesh Size Depending On Different Usage Conditions And Purposes. It Has Good Filtration Performance For 1-500um Particles And Liquids, With A Large Flow Rate Per Unit Area. After Cleaning, It Can Be Reused Repeatedly. Its Characteristics Are High Absolute Concentricity, High Pressure Resistance, Good Straightness, No Burrs, And Long Service Life.

Materials Include 304, 304l, 316, 316l Stainless Steel Punching Mesh, Woven Mesh, Welded Mesh, Brass Mesh, Aluminum Foil Mesh, Etc

Application:

1. Petrochemical And Oilfield Pipeline Filtration;;

2. Fuel Filtration For Refueling Equipment And Construction Machinery Equipment;

3. Equipment Filtration In The Water Treatment Industry;

4. Pharmaceutical And Food Processing Fields;

Ultra Large Filter Cartridge

Filter Material: Woven Or Punched Mesh Made Of Stainless Steel Such As 304, 304l, 316, 316l, 317l, 904l, As Well As Materials Such As Monel And Hastelloy.

Divided By Shape: Conical, Straight Cylindrical, Inclined, Etc.

Classified By Structure: Single-Layer, Multi-Layer Composite, And Combination.

Size: Diameter Greater Than 1.5m, Height Greater Than 4m.

Applicable Industry: Pipeline Filtration In The Petrochemical Industry.

Filter Material: Woven Or Punched Mesh Made Of Stainless Steel Such As 304, 304l, 316, 316l, 317l, 904l, As Well As Materials Such As Monel And Hastelloy.

Divided By Shape: Straight Or Inclined Cone; Etc.

Classified By Structure: Single-Layer Mesh Or Multi-Layer Mesh Or Merged Mesh.

Size: Diameter ≥ 1.5m, Height ≥ 4m

Application Industry: Petrochemical Pipeline System Filtration

Filter Mesh

The Filter Mesh Is Processed By A Special Mold Through A Punch Press, Using Rare Metal Products Such As Stainless Steel Mesh And Black Silk Cloth As Raw Materials. Generally Used In Petroleum, Chemical, Pharmaceutical, And Chemical Plants.

The Filter Mesh Is Processed By A Special Mold Through A Punch Press, Using Rare Metal Products Such As Stainless Steel Mesh And Black Silk Cloth As Raw Materials. Generally Used In Petroleum, Chemical, Pharmaceutical, And Chemical Plants.

Shape: Rectangular, Square, Circular, Irregular

Product Structure: Single-Layer, Double-Layer, Multi-Layer.

The Main Materials For Filter Plates Include Stainless Steel Fiber Sintered Felt, Stainless Steel Woven Mesh, Phosphor Copper Mesh, Brass Mesh, Etc. The Edge Wrapping Materials Include Aluminum, Stainless Steel, Copper Nickel Plating, Etc. The Filter Material Can Be A Single Layer Or Multiple Layers. Filters Are Divided Into Circular, Rectangular, Waist Shaped, Elliptical, Etc. According To Their Shape

Application:

Mainly Used For Impurity Filtration In Polyester Film And Synthetic Fiber Spinning. Rectangular, Square, Circular, Elliptical, Circular, Rectangular, Hat Shaped, Waist Shaped, Irregular.

Product Structure: Filter Mesh. Product Structures Include Single-Layer, Double-Layer, And Multi-Layer

Craftsmanship: Double Or Triple Layer Spot Welding, With Welding Points Generally Ranging From 4-10, And Single-Layer Or Double-Layer Edging Can Also Be Done According To Customer Requirements.

Materials: Stainless Steel Mesh, Galvanized Mesh, Copper Mesh, Dense Mesh, Punched Mesh, Etc

Edge Wrapping Materials: Stainless Steel Plate, Copper Plate, Galvanized Plate, Aluminum Plate, Rubber, Etc

Filter Diameter: Generally 5 Millimeters To 600 Millimeters. Filters, Filter Combination Products (Also Known As Filters), Are Mainly Used In Processes Such As Distillation, Absorption, Evaporation, And Filtration In Industries Such As Rubber, Plastic, Grain And Oil Screening, Petroleum, Refining, Chemical, Light Industry, Medicine, Metallurgy, Machinery, Ships, Automobiles, And Tractors. They Eliminate Droplets And Foam Carried In Steam Or Gas, And Are Used As Air Filters In Automobiles

Candle Shaped Filter Element

1. Good Breathability;

2.2. Good Corrosion Resistance, Heat Resistance, Pressure Resistance, And Wear Resistance;

3.3. Uniform Pores And High Filtration Accuracy;

4.4. High Flow Rate Per Unit Area;

5.5. Use Ultrasonic Waves, Chemical Reagents, And Other Methods For Cleaning. After Cleaning, It Can Be Reused Without Replacement.

Filter Material: Mainly Woven Mesh, Fiber Sintered Felt, Sintered Mesh Of Stainless Steel Such As 304, 304l, 316, 316l, 317l, 904l, Monel Alloy, Hastelloy Alloy And Other Materials.

Characteristic:

1. Good Breathability;

2. Good Corrosion Resistance, Heat Resistance, Pressure Resistance, And Wear Resistance;

3. Uniform Pores And High Filtration Accuracy;

4. High Flow Rate Per Unit Area;

5. Use Ultrasonic Waves, Chemical Reagents, And Other Methods For Cleaning. After Cleaning, It Can Be Reused Without Replacement.

Application Industry:

1. Polymer Industry: Production Fields Such As Synthetic Fibers, Plastics, And Film;;

2. Petrochemical Industry: Petrochemical, Oil Refining, Paint Refining, Etc;

3. Pharmaceuticals And Food: Synthesis, Refining, Catalytic Recovery Of Drugs And Food;

4. Machinery And Ships: Hydraulic Production Lines And Cutting Oil;

5. Gas And Natural Gas Flow Control Field;;

6. Sterilization And Filtration For Air Purification And Water Treatment;

7. Other: High Temperature, High Viscosity, High-Pressure Fields.

Thin Disc-Shaped Filter Element

Filter Material: The Main Filter Materials Used Are Metal Fiber Sintered Felt, Multi-Layer Metal Sintered Mesh Plate, And Metal Woven Mesh.

Characteristic:

1. Excellent Filtering Ability And Long Lifespan;

2. Can Adjust The Filter Size: Filter Solids Are Large And Flow Is High: Regeneration Is Possible;

3. Good Rigidity And Accurate Filtration Accuracy. Can Be Repeatedly Rinsed And Used For A Long Time;

4. The Filtration Accuracy Is 0.5-200um With A Diameter Of 200-300mm, And The Filter Disc Structure Has Both Integral And Split Types.

Application Industry:

Polymer Filtration (Polymer Filtration In The Plastic Industry); For Weaving Stretch Film (Film); Used For Purification In Petrochemical Industry.

Common Specifications:

1. The Woven Wire Mesh Is Based On Porous Plates

2. Filter Material: Filter Layer - Sus 316l, Protective Layer - Sus316304;

3. Porosity: 70-85%;

4. Filtering Direction: From Outside To Inside;

5. Maximum Pressure Difference: 120kg/Square Centimeter.